Troubleshooting and Maintenance of Wood-plastic Machines

main content

First, the wood products manufacturing problems to be solved

Second, the status of domestic wood equipment and the comparative analysis

Operating three wood equipment

Fourth, wood equipment repair and maintenance

Fifth, failure analysis and processing

First, the wood products manufacturing problems to be solved

It must be addressed in order to make wood products equipment, molds and process recipe the following questions:

1, process issues

1) source of raw materials

①, plant fiber sources to stabilize

②, plastics sources

③, additive

2), water issues plant fibers

①, special drying equipment, such as: air drying machine.

②, rely on equipment to achieve.

3), plastics and fiber interfacial bond issue

The main problem is the recipe to make two different polar substances combine enough. Now a lot of solutions.

3), a suitable process temperature. In ensuring plasticized premise, the temperature as low as possible.

2, hardware (equipment and tooling)

1), the addition is not to be neglected

①, to solve the problem of bridging flour, in order to ensure the continuity of cutting, in order to make a good product.

Cutting uniformity problem ②, wood flour and plastic (most equipment manufacturers have not been resolved. Causing plastic additive amount increases to make it right the problem of uneven charging).

2), kneaded, plasticized, exhaust

Must be mixing plastics good equipment, can be achieved. Such as using the same parallel twin-screw device; his advantage, mixing plastics, good exhaust effect, is engineering plastics granulation equipment, two-step process, with his granulation, one-step, with his mixing plastics Other devices directly into the extruder, the effect is more pronounced.

3), mold design and cooling shaping technology.

The nose is related to the important parts of the extruded product quality, due to the high amount of WPC addition particularity of the extruded material and wood flour illiquid and difficult to cool, the conventional mold and shaping equipment has been unable to meet the needs of the This makes the head of design in addition to ensuring a smooth transition outer flow channel design with a reasonable flow distribution, but also on the ability of the nose to build pressure and temperature control accuracy important consideration. Liquidity WPC poor, the mold should try not to use baffle blocks and other structures, but should be used to adjust the flow rate of the flow channel cross section by changing the flow channel size; in the mold of sufficient strength, minimize the number of brackets and ribs size; and the use of a large compression ratio, in order to ensure greater the extrusion pressure, in order to facilitate molding. Based on the thermal sensitivity of WPC, the mold should adopt a larger structure size to increase the heat capacity, so that the whole head temperature stability can be strengthened; and the extrusion direction dimension whichever is less, to shorten the material in the handpiece residence time; and rational arrangement of the handpiece heating and cooling device, making it the heating and cooling speed, high precision. British design the flowable die, without the use of a perforated plate, may also cooling the inner surface of the hollow profile, reduced melt pressure and increased yield.

3), Flowing fibers

Structure ① rely on equipment to solve.

② the degree of fiber orientation in WPC have a greater impact on product performance, reasonable design flow channel structure, to obtain a suitable fiber orientation to meet the performance requirements of the article.

3, the operation

Second, the status of domestic wood equipment and the comparative analysis

A), the status of domestic wood equipment

So far, the WPC device equipment single screw, conical twin-screw and one-step equipment. The former, performance products, mainly by process recipe to adjust, adjust narrow face; the quality of products affected to some degree. The latter, one-step devices come and processes, formulas addressed through structural performance of the device.

B) The comparative analysis of the various devices

Development of domestic wood equipment began in 1999, now has more than 6--7 years time. Through unremitting efforts of domestic equipment manufacturers have gradually matured, affordable products to meet the production, in order to reach the international advanced level there is still a long way to go. Domestic wood equipment at one-step and two-step method; and most of the domestic two-step method, the first dry granulation, and then extruded. Nanjing tournament Mong company after years of efforts to develop a special wood-step (patent) equipment.

1, single-screw extruder

Single-screw extruder can complete the task delivery and plastics materials. However, the role of a single-screw extruder delivery mainly by friction, because the wood flour fluffy structure, easy to extruder screw feeder, a longer residence time in the barrel, and wood flour filled polymer melt viscosity increases, increasing the difficulty of extrusion; and poor exhaust its effects; as well as its mixing plastics is not strong. Therefore, a single screw extruder by the WPC extrusion greater restrictions, the use of single-screw extruder screw must be specially designed screw should have a strong conveying and mixing plastics capabilities, Often the material for mixing prior to extrusion granulation.

Problems: Exhaust poor; poor mixing effect; extruded product pressure fluctuations; low yields.

2, the conical twin-screw extruder

And "compounded" apparatus than, different to the conical twin screw extruder is called low-speed, low-power "profiles" apparatus. Feeding section diameter of the tapered screw is larger, the material can be continuously compressed. You can shorten the material in the machine barrel residence time, and the metering section diameter small, shearing the molten material, which for the purposes of processing heat-sensitive WPC is a big advantage.

Conical twin-screw must be specially designed. To meet the wide thermal resin processing requirements, there are many new features and demands to be able to adapt to the working range of the screw, to cut less wood fiber, resin is small can still make the wood fibers are uniformly dispersed and the material is completely melted. Because wood flour, vegetable fiber proportion of small, filled with large, feeding zone volume than conventional models of Japanese long. If wood flour, vegetable fiber added in an amount of molten resin rigidity, resistance to high backpressure requirements gearbox, screw pushing strong, using compression and melting fast, short metering section of the screw, to ensure wood fiber residence time is short, to prevent its rupture and performance degradation. But because of its screw structurally integral, it is difficult to meet the requirements of different process recipe, and mixing effect extruder worse than parallel twin-screw, easy to wear and tear, but also granulated.

3, different to the parallel twin-screw extruder

Iso can be processed directly to the parallel twin-screw extruder flour or plant fibers. So, to be completed and dry before wood flour molten resin is melted separately. You can also use another parallel twin-screw extruder, its front to dehydration, devolatilizer, wood flour ingredient added to the extruder mouth, dehydration, devolatilization, then add plastic resins, additives through a side feeder, plasticized extrusion. Thus, a relatively long extruder screw aspect ratio (L / D) up to 44 to 48, in which two-thirds is used in addition to water and devolatilization. This enables the melt processing step lower melting temperature, to avoid the risk of melt sintering. But also help to ensure that the next sawdust mixed uniformity and control the proportion of wood / plastics. However, the moisture content of the wood flour has certain requirements, the device easy to wear. Domestic rarely used.

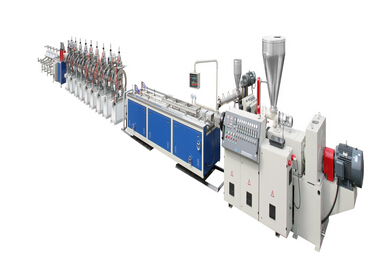

4, wood-step special (patent) equipment

As we all know, in the same direction parallel twin-screw granulation equipment is plastic, it has good mixing, good dispersion, dehydration, dehumidification lined up waving good advantage, while using a single screw build pressure function. Give full play to the advantages of parallel twin screw and a single screw. This special equipment, no drying, no granulation, significant energy savings, high dosage. While adding fiberglass, improve product strength (also widely used abroad).

Race Wong developed special wood-step (patent) equipment, is a national initiative, the international community has the leading position. It has now won four national patents.

Equipment advantages:

High quality: a number of national patents; rational design, fine workmanship, sophisticated material, durable.

High efficiency: mixing plastics good, good liquidity extrusion speed, high efficiency.

Ko Tim charge: mixing plastics good, good dispersion, high added (the amount of 70% plant fiber).

Power consumption: no granulation, significant energy saving (40% energy saving compared with their equipment)

Long life: barrel and screw element with special materials and long service life (15,000 hours).

Apply a wide range: can be used to produce PP, PE, PVC, ABS, PS and various plant fibers. In order to increase product strength, glass fiber may be added.

Equipment and technology issues:

A) raw materials - how to improve the interface between the plastic and wood flour compatibility;

My company after a long period of research experiments, summed up the processing plant fiber interface of different methods, such as: wood flour; bamboo powder; rice bran; peanut shells; bagasse; Cotton rods; corn rods; rice straw; straw; and a milk box other treatment methods, has received very good results can be made according to customer requirements formulation process.

B), feeding, devolatilization, plastics, dispersion

1, feeding Question: I am using the accurate measurement of two feeders, feeding separately to ensure accurate feed to prevent because of different specific gravity, and the problem of uneven charging.

2, effective devolatilization (ie remove water), to improve the system blending wood flour dispersed: I am using the same parallel twin-screw, a plurality of exhaust port for devolatilization remove water; use parallel twin-screw extruder mixing, plasticizing, dispersion and good, redesigned barrel and screw element to produce wood. Changes using a parallel twin screw modular principle, different plastics and reprocessing plant fiber threaded element combination, you can achieve a wide range of applications.

3, set the appropriate extrusion temperatures and build up enough pressure to ensure the performance of molded product:

In order to solve the pressure problem, we used a single screw, parallel twin-screw to Thee fill pressure is not built up enough.

In the process control PLC control we use, so that the host and traction machine adopts closed loop control, to avoid the host speed and traction speed mismatch. Temperature smart thermostat meter or PLC control.

C), mold design and cooling shaping technology:

WPC extrusion mold is the speed and quality of products bottle diameter, over the years we have accumulated a wealth of experience in mold design and manufacture, such as; hollow products; solid products runner how design, compression ratio much; how wide plate mold design and many more. Now my company equipment extrusion products speed is relatively high. Cooling stereotypes according to different profiles, choose different cooling.

5, granulation equipment:

① parallel twin-screw granulation equipment.

Parallel twin-screw device advantage

Two metering feeder, make wood flour and plastic are feeding, to ensure accurate feeding. Make wood flour and plastic mixing, dispersing, burden, connected, thus ensuring the quality of products. Avoid the phenomenon due to the large difference between the proportion of plastic and wood flour to produce stratified during the addition, and affect product quality.

① using a specially designed threaded element, so that flour and plastic conveying and mixing plastics good effect.

② using specially crafted vents, remove residual moisture wood flour, to ensure product quality.

③ large aspect ratio (40: 1), so that the barrel heating temperature is low, to prevent the wood flour carbonation; a moisture exclude more fully; better mixing effect.

④ special head design, diced ensure uniform and reliable.

⑤ threaded element of special materials, long service life.

Conical twin screw

② conical twin-screw

Mixing plastics, poor, poor exhaust, the device easy to wear.

Operating three wood equipment

A) extruder operating and maintenance precautions

WPC equipment rules

(1), in strict accordance with equipment operating instructions.

(2), is prohibited in the extruder barrel vent poke at the metal holding material to avoid damage to the barrel and the screw, the correct approach is to use plastic pipe or wood profiles;

(3) Before extruder heating power needs in advance step by step, after heating to the set temperature for one hour before boot. Some of the feed screw with a heating device, feed screw and began warming in the boot, at the time of shutdown, should first feed screw cooling, in order to avoid material sticking.

(A), the preparatory work before starting

Host:

1) Check the feeder, hopper, barrel without foreign body, if any foreign body must be clean.

2) Check the screw and barrel cooler cooled oil cooler (simethicone) the amount, must meet the standard requirements. If the cylinder is cooled by the cooling fan, you need to check it is intact.

Auxiliary:

1) Check the cooling water tank water level reaches the standard.

2) Check the cutting hood inside, are not allowed to affect the rotation of the blade object exists.

3) Check the gas line in each lubricator oil level, and drain cleaner.

Mold installation:

1), put the host manifold outlet (this according to the actual need to determine whether to use, install the washer is not installed manifold), mold aligned horizontal alignment (horizontal foot) Tighten the bolts (note bolts tightness must be consistent, mold flange and host flange gap equal).

2), in order to correspond to the heating plate and thermocouple fixed on the mold, heating plate must fit tightly and die, and die by the thermocouple to reality.

Calibrator and cooling water tank installation:

1), the calibrator fixed stereotypes on stage, and in alignment with the mold on.

2), respectively the vacuum port, cooling water connection and setting the stage one by one vacuum port, cooling water interface corresponds to the coupling (with easy operation order).

3), the cooling water tank placed in the stage setting and alignment with the calibrator pair.

After completion of the above work, closing the mains, open the inlet valve and air valve, conduct inspection division. Division before testing, please read the "User Manual", according to the manual procedures, each of the following parts of the test;

Cooling pump: positive pressure showed that after a period of time to view the user interface if that part of the temperature change (warming?).

Inspection of:

A, host vacuum pump: a vacuum table to have a negative display.

B, master cylinder and mold electric heating coil: is intact, normal temperature.

C, stereotypes vacuum pumps, circulating pumps: pressure gauges have no negative, positive pressure display.

D, traction equipment: (1) Tracked opening and closing properly; (2) the input pressure reaches 0.45-0.5Mpa, tracked up and down pressure should be 0.25Mpa; (3) adjusting the speed selection: manual (potentiometer regulation), automatic all normal regulation.

E, cutting machines: manual and automatic (computer screen regulation) Cutting normal.

(B), the boot program:

1, set on the feeder feeding time, intermittent time (actual extrusion process needs to be set).

2, set the barrel, mold, screw temperature (ibid.).

3, set the holding time (3600s, to secure the actual extrusion process, and the need to set the device);

When the master cylinder, mold, screw temperature reaches the set temperature, holding time starts counting down; the countdown procedure is in progress, the host is protected can not be started. Therefore, in order to save energy, the heating time does not have to screw with the host machine cylinder begin simultaneously. Time to master to ensure minimum time to reach the heating power requirement shall prevail.

4, when the countdown ends;

1) by the mixed raw materials were added to the feeder hopper, metering feeder open, adjust the speed - from low speed began to adjust;

2) Turn on the host screw, adjust the speed - from low speed began to adjust, and ≯2rpm, in this case, no material empty start; if there are material barrel, you must start from zero speed, while the melt pressure must 2Mpa the following;

Speed metering feeder screw speed with the host principles:

① seen from the windows, the host of the screw above the basic material does not exist;

② based Host torque (≯7.5NM, melt pressure ≯25Mpa, and vacuum vent no powdered materials (to allow a very small amount) is discharged therefrom;

The actual situation ③ plastics molding profiles.

3) When viewed from the host material to vent to, you can open the vacuum exhaust unit, and at the same time you can adjust the feeder feeding quantity, so that the host of the screw inside the rapid formation of "material force" in order to achieve a higher degree of vacuum . And timely switch to clean.

4) When the material extruded from the die, plastics observation of materials, molding conditions, such as normal to synchrotron (with the host feeder screw); you should pay attention melt pressure and torque show host value, this Two indices are alert limits, beyond the limit at which a particular value or long-term operation at the critical limits will cause damage to the device. Exceeds a set value alarm.

5) Profile of traction:

Slow to profile extrusion conditions, so the profile through a calibrator, cooling tank to a tractor; in this case should be based on the profile of the forward speed, adjust the speed of the crawler tractor, when both basic synchronized when the folder is closed TRACK holding profiles.

Note: The vacuum can not be turned, only to water cooling setting; when the profiles are clamped crawler tractor only after opening the vacuum, implementation of a complete cooling operation stereotypes. No matter how high or low extrusion speed, tractor speed adjustment should always be shaped and extruded products to match the state (in normal production, can also be turned traction, melt pressure closed-loop system to keep the automatic control state).

6) To the profile surface embossing and typing, it should open the far-infrared heating device, adjust the height of good embossing roll from typing device, then turn on the profile surface air ring cooling after the embossing.

7) automatic cutting profiles:

Setting profiles by forming a switch or computer screen size and cut length pusher length dimensions. When the profile reaches the set value, automatically cutting saws for cutting, flip frame automatically pushed expect material rack.

(Iii), stop the program:

1, first turn off the feeder; rear and feeder speed down, close the feeder.

2, when the observed amount of material extruded from the die noticeably small, off the heating system and mold cylinder, closed screw cooling devices, vacuum exhaust, and the screw speed zero after turning off the host.

3, close stereotypes station cooling and vacuum systems.

4, will move after shaping table, leave space disassembly of the mold (in case if you need to disassemble the mold under).

5, when the profile entirely by tractor, shut embossing system, typing system, traction machine, cutting systems.

6, such as the need to replace the mold, you can maintain the status quo. To replace the mold, the mold temperature should be lowered a little while rapid disassembly, cleaning out the material and the host interface connecting ring at. Note: You can not hurt the pressure sensor chip host interface when cleaning! !

7, using compressed air forming table, dragger, water stains and residue material cutting device clean.

8, closed production line total power, water, compressed air source.

(Iv) Notes:

1, high-temperature mold heating portion could easily lead to burns, must wear protective gloves when operating.

2, when the normal operation of the tractor crawler, not free to open the fence; prohibited repair and maintenance in the tractor running, to prevent accidental entrapment.

3, cutting saws produce non-open view during the operation, repair, maintenance, must cut off the power and air supply.

4, prohibited the use of iron into the extruder barrel internal poke, pry. Especially in front of the confluence of the core barrel pressure sensor site.

5. Removal of mold and calibrator, when exposed to the inner surface of the mounting surface must be made of copper tools, prohibited the use of iron utensils! To prevent the flow channel, forming surface and the mating surface is scratched.

6, the heating coil under demolition, bolts, etc. is prohibited on stereotypes within the station tank, it must be placed on the surface of a dry table; when using a threaded bolt again must brush silicone oil.

Fourth, wood equipment repair and maintenance

Maintenance Content:

Routine maintenance by the operator on a daily basis, the main contents are: clean, lubricate and check the status and fastening parts complete loose parts.

1), a maintenance of the main contents are:

An apparatus according to usage, for some parts removed and cleaned; some with the clearance of the equipment make the appropriate adjustments; clean surface oil, lubricating oil passage to check the adjustment, ensure the smooth flow does not leak; cleaning electrical boxes, motors, electrical devices, do fixed tidy, reliable security guards; cleaning accessories and cooling devices. Level maintenance shall be directed at a full-time maintenance workers, borne by the operation of the workers.

2), two maintenance main contents are:

An apparatus according to usage, a partial disintegration of the equipment inspection and cleaning; cleaning oil change for a variety of housing, fuel oil to meet the requirements, to ensure the normal lubrication; repair, replacement of wearing parts; repair electrical box, motor, line; inspection, adjustment, repair accuracy, correction levels. Secondary care overhaul undertaken by full-time workers, workers in the operation to assist.

A) extruding machine repair and maintenance:

(1), always check the extruder internal temperature heating and cooling tank tank tank oil level and oil condition, if found to reduce oil and oil stain in place to immediately supplement or replace.

(2) only when the confluence of the extruder head plastic core was molten state, allowed to disassemble the pressure sensor can be used to clean the hard tools allowed the plastic confluence within the core, otherwise it will damage the pressure sensor interface .

(3), the extruder must always check the data on the computer screen or the operating instructions of the instrument, especially the host torque display and merging core melt body pressure display, if the display exceeds the limits prescribed extruder need immediate stop to check and take timely measures to resolve. Normal operating pressure should be less than 20Mpa, with about 15Mpa more moderate, also at 45Nm ~ 60Nm torque in.

(4), check the fluid level regularly each extruder gearbox oil level height and screw the thermostat tank, promptly added to the corresponding grades of lubricating oil and thermal oil. After half a year, you should check the quality of all types of oil and timely replacement.

(5) added to the feed hopper of the extruder are not allowed inside the metal debris mixed to ensure that the screw and barrel from damage. In the hopper equipped with a magnetic holder, regularly check for and remove adsorbed on a magnetic rack metal debris.

(6), the extruder is found abnormal noise during operation, should immediately stop inspection, troubleshooting and then boot.

(7), extrusion confidential kept clean and well lubricated condition. Ready to do the electrical cabinets, console the wiping and lubricating work. The working parts of the machine should always be dust, decontamination, in addition to impurities.

B) powder feeding machine repair and maintenance and precautions:

1, repair and maintenance:

(1) should be checked once a week and feeding the spring motor coupling is reliable to prevent feeding spring loose or fasteners falling into the hopper and damage the host, and always check whether there is debris on the wound spring.

(2), always check the work on the feeder spring and cover between the nylon tube, such as nylon tube badly worn should be replaced.

2 Notes:

(1), the feeding of the spring and the motor coupling sleeve fixing screws, electrical connection sleeve and the motor shaft fixing screws can not be demolished.

(2), aircraft and definitely not reversed, otherwise it will damage the machine.

C) the extruder screw core tempering device maintenance and precautions:

1, the extruder screw core tempering equipment maintenance:

Screw core tempering device should be checked for loose fittings, oil spills, leaking, if found to reduce oil supplement that is played; in hard water area, we recommend regular demineralized water in the cooling water by adding a solvent to prevent the wall of the cooling system have a scale impact of cooling water capacity.

2, Notice:

(1) Clean the screw HTF must be filtered before use, in order to ensure a constant temperature system is normal, after working 2,000 hours a screw, you must check oil conducting oil and cleaning oil filter, so the oil flow;

(2) Screw HTF full heating cylinder, it checked before heating up:

a, view over the exhaust pipe is heated cylinder oil benefits;

b, Check the pressure gauge is stable (maximum system pressure is defined by a high temperature safety valve, the factory before it is set, the user can not be adjusted);

(3) conducting oil tank should always check the oil level, the pump can not be started when the discovery or the oil level should be less than 1/5 the height of fuel tank to 1/2 position;

(4), oil use can not continue to be used after retirement index, otherwise it will lead to a fire hazard accident, must attach great importance. HTF for reference scrapped indicators are as follows:

a, carbon residue than 1.5%

b, the acid value exceeds 0.5mgKOH / g

c, flash point below 130 ℃

Note: The above three indicators as long as there is a scrap reached should be scrapped.

D), the extruder breakdown and repair

1. The reason for failure of the machine can occur and elimination methods are as follows:

Extruder Symptom

cause

Eliminate It

Heating parts

Hot and cold

First, the oil system

1, oil (water) pipes and working chamber or working chamber channel is too narrow for the large long positions serpentine channel resistance.

2, oil (water) pipes and working chamber obstruction, there are deposits or other debris blocked the dirt.

3, the solenoid valve malfunction.

Second, the air cooling system

1. Check the heating and motor control circuit is working properly.

2, check the thermocouple is working.

First, the oil system

1, clean up and clear passage (water) pipes.

(Short hose with the general output port and the return port socket, check inside the duct obstruction, then strengthen dredge)

2, replace the solenoid valve.

Second, the air cooling system

Replacement of electrical accessories, to make it work properly.

Unheated

The heating element is damaged

Replace the heating element

Without cooling

1, the water supply tank water

2, the solenoid valve failure

3, there is a greater drain back pressure

1, trying to increase water pressure

2, overhaul or replace the solenoid valve

3, sparsely exclude drainage pipe backpressure

Output pressure is zero

Suction line blocked

Check the load and piping

2, the oil pump oil seal leak repair method:

Pump seal is wearing parts, when the long-running or blocking the oil, are likely to cause oil seal leak. After the oil pump run for six months, it must be replaced seals. The disassembly of the seal as follows:

A, front pump seal removal

1) Remove the oil pump drive shaft end and the motor bracket at the screws.

2), before removing the oil pump and the oil pump cover, replace the seal.

3) When replacing seals, pay attention to the seal hole clean debris and coated with oil, then use special tools to press-fit the oil seal. (Be careful not to mess with a hard object damage pry side seal)

4), according to the above in reverse order so the front cover fitted, can be fixed with screws.

B, pump cover disassembly

1) Remove the cover and pump coupling screws and remove the cover.

2) Remove the O-ring, to see whether the deformation, such as deformation is required for the same type of high-temperature O-ring.

3), according to the above is installed in reverse order, requiring cover and pump coupling two flat clean.

E) the vacuum exhaust system

(A), the system's maintenance:

1, the system running for some time, if found pumping rate decreases, pump heavier sound, indicating the need for a vacuum tank filter clean or replace the filter, the extruder may be at work, set the operation of the rotary valve to the service position quickly remove the transparent sheet and the filter on the vacuum tank, cleaning or replacement is completed for a short time after recovery, set the rotary valve in working position can be, if the extruder is sufficient parking time, you can completely clear the vacuum tank and suction pipeline.

2, if the extruder long-stay parking, water pumps shall within drained through drain port, especially should pay attention to the freezing season, to prevent the cracking of a vacuum pump.

3, if the higher operating water hardness, then at least once every six months to open the vacuum pump to remove the inside scale.

(B), system failure and exclusion:

1, vacuum suction is not enough:

a, checking the tightness of the vacuum pump suction duct;

b, check the vacuum pump dirty conditions;

c, check the vacuum tank filter is clogged.

2, there is a large vacuum pump noise:

a, check the vacuum level is too high, you can adjust the exhaust vacuum tank bottom drain valve, reducing the degree of vacuum troubleshooting;

b, check the water supply quantity is too large, adjust the amount of water to be eliminated;

c, check the filter is blocked, such as the blockage is clean replacement.

3, vacuum pump, vacuum tank leak

Replace the gasket or sealing valve

VI), auxiliary, stereotypes Taiwan, spray tank Caution

1, tractor work should be avoided hitting profile cutting saws, always clean cut sawing cuttings.

2, shaping table should be kept clean and free of debris to ensure smooth flow of water at reflux, regular cleaning of pumps, gas water separator filters through the water, in order to ensure the normal operation.

3, should be kept clean and free of debris inside the spray tank, you need to regularly clean the pump filter.

Profile production is not a normal phenomenon, causes and solutions

Irregularities

the reason

Solution

1, profiles stagnation

A, the melt pressure is too high

B, traction system failure

A, down, down, low speed and then boot

B, traction system overhaul

2, profiles fracture

A, the melt pressure is too high

B, pulling too fast

C, plus quantity is too small

D, charging system failure

A, shut down, and then boot

B, reducing traction speed to match the speed and profile extrusion

C, increase feeding quantity

D, charging system overhaul

3, the melt pressure is too high torque is too high

A, low temperature, the material is not plasticized

B, charging excessive

C, screw speed too high

D, pulling too fast

A, raising the temperature, strengthening plastics

B, reduce feeding quantity

C, reducing the screw speed

D, reducing traction speed

4, the profile surface with bubbles

A, the raw material in the water or volatile substances

B, vacuum exhaust system failure

A, dry feedstock

B, the vacuum system overhaul

5, sections scratches the surface of the continuous extrusion direction

A, cavity scratches

B, the mold cavity with debris

A, grinding cavity

B, clean up the mold cavity

6, lack of surface gloss profiles

A, plus enough quantity

B, head temperature is not enough

C, excessive impurities in the material

D, head pressure is not enough

A, improve feeding quantity

B, improve head temperature

C, remove impurities in the material

D, maintaining sufficient head pressure

7, profile bending

A, cooling setting temperature discomfort

B, nose and stereotypes die and sink the tractor is not in the center of the horizontal line

C, sections stacked unreasonable

A, adjust the amount of cooling water

B, adjust the center level

C, re-laying is reasonable

Fifth, failure analysis and processing

1. General

When failure analysis, first understand the working principle and structure of each part of the device. Once you've mastered its working principle and structure, we will be aware of the occurrence of the problem fundamentally, then gradually find out the root of the problem. Be sure to read the product manual carefully.

2, Common Cause and Treatment

1) Main motor current is too large, given the rhythmic sound of friction

(1) single screw and barrel arm had local friction, whether open screw inspection and gearbox connection dirt.

(3) issued by the rhythmic sound of friction is sometimes caused by single screw without material, it should increase the feed speed to increase feed.

(4) small motor current feedback to produce crawling, should re-adjust the amount of feedback.

(5) Screw the motor current is too large,

2) The main motor can not start

(1) single-screw main motor can not start a barrel temperature does not reach a certain set value, should continue to heat up;

(2) a power failure, check the power and troubleshooting.

3) The main motor idling, do not turn the screw

Safety pin broken, replace the safety pin should be shut down immediately.

4) Barrel heating reach the set temperature

Causes and Remedy:

a heater is damaged, replace the heater;

b power supply is bad, or this paragraph power fuse is damaged, replace the insurance, re-connect the power cord;

c When the temperature is lowered to below the set value, the temperature controller does not turn on, replace the temperature controller;

d thermocouple is damaged, replace the thermocouple;

e thermocouple or heater wrong location, adjust the leads, open the heating switch;

f thermocouple is not attached to the bottom of the casing, should reposition thermocouple;

g controlled cooling of the solenoid valve stuck in the open position or the solenoid valve is not powered up, the solenoid valve should be repaired or replaced.

5) heating zone temperature exceeds the set value

(1) heating zone temperature exceeds the set value, the temperature controller does not turn off, replace the temperature controller;

(2) thermocouple is damaged, replace the thermocouple;

(3) thermocouples or heaters in the area are wrong, and should accordingly lead and open the heating switch;

(4) The safety valve cylinder cooling device stuck in the open position, the safety valve should be repaired or replaced;

(5) Control area cooling solenoid valve stuck in the closed position or the solenoid valve is not activated, shall repair or replace the solenoid valve or repair the circuit;

(6) the pump or motor cylinder cooling device is damaged, repair or replace the pump or motor;

(7) flows through the barrel cooling means insufficient water cooler, cooler that is blocked or water pressure is too low, you should repair or replace the cooler, try to increase the pressure to meet the requirements;

6) the degree of vacuum is too low

(1) piping system leak, leak location should be isolated, and then be replaced;

(2) Cylinder windows at or vacuum tank seal failure or damage, etc., should be replaced;

(3) vacuum inadequate water supply.

7) the exhaust port to take the material, the linker risk material

(1) take the material exhaust port

a, charging excessive, reduce the feed screw speed;

b, screw excessive wear, the screw should be adjusted or replaced;

(2) single linker risk material

a screw temperature is too high, screw core cooling water barrier;

b feed inlet temperature, cooling water barrier;

Severe vibration 8) Equipment

(1) coupled to the motor shaft and the gear box at the concentricity error is too large, should be readjusted;

(2) The motor bearing excessive wear or damage should be replaced bearings;

(3) gearbox bearing failure, replace the bearings;

(4) did not leveling ground, fishing stationary frame;

(5) Cylinder support loose, can not afford a supporting role.

9) extruder can not be restarted

(1) The emergency stop button is not reset, reset;

(2) The power switch is not turned on, you should unplug the power to the open position;

(3) The main circuit fuse burned out or not attached to the core, should be replaced or installed;

(4) The main circuit thermal relay trip, it should reset the protection system, turn the heat relay.

Thermocouple Troubleshooting and treatment in the following table

malfunction

the reason

Method of exclusion

Thermocouple

Than the actual value

Smaller (instrument

Table itself

No fault, but

Indication low)

1. The thermocouple inside the drain electrode

2. Internal wiring shorted junction box

3. The compensation wire short circuit

The thermocouple electrode deterioration

5. improperly located

6. thermocouple indexing instrument inconsistent

1. detect leakage causes and ruled out

2. Eliminate short circuit fault

3. The short-circuit re-insulation or replace

4. Replace

5. Reinstall

6. Replace consistent thermocouple indexing number

Thermocouple

Than the actual value

Bigger

1. thermocouple indexing table is inconsistent

2. compensation wire and thermoelectric power are inconsistent

3. thermocouples installed the wrong place

1. Replace

2. Replace

3. Select the correct mounting position

Instrument display

Unstable

(No fault of the instrument itself)

SKY WIN Technology Co., Ltd. is a high-tech joint-stock enterprise which combines research, manufacture and sales of WPC (wood-plastic composites) extrusion machines in China.In the past 10 years, many experts in SKY WIN have concentrated on WPC extrusion lines (granulators, extruders, upstream and downstream machines, etc.) and now the company has accumulated a lot of experience on WPC equipment, molds, technical formula, and products.SKY WIN wood-plastic machines are sold to over 200 customers in China, and over 30 customers in foreign countries, such as Itly, Russia, Poland, Singapore, Thailand, Saudi Arabia, UAE, Honduras, etc..

SKY WIN Technology Co., Ltd. is a high-tech joint-stock enterprise which combines research, manufacture and sales of WPC (wood-plastic composites) extrusion machines in China.In the past 10 years, many experts in SKY WIN have concentrated on WPC extrusion lines (granulators, extruders, upstream and downstream machines, etc.) and now the company has accumulated a lot of experience on WPC equipment, molds, technical formula, and products.SKY WIN wood-plastic machines are sold to over 200 customers in China, and over 30 customers in foreign countries, such as Itly, Russia, Poland, Singapore, Thailand, Saudi Arabia, UAE, Honduras, etc..

苏公网安备32011202000012号

苏公网安备32011202000012号