- Home

- SKY WIN

About SKY WIN

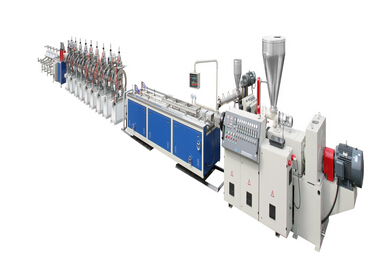

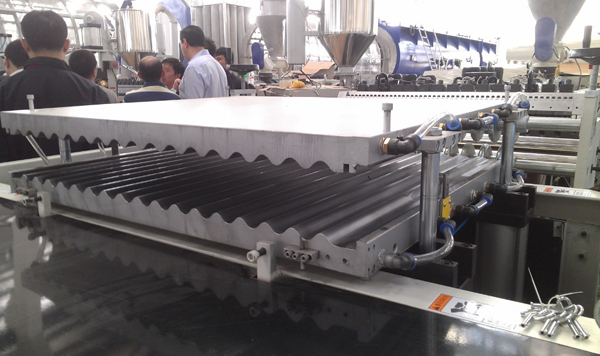

SKY WIN Technology Co., Ltd. is a high-tech joint-stock enterprise which combines research, manufacture and sales of WPC (wood-plastic composites) extrusion machines in China.In the past 10 years, many experts in SKY WIN have concentrated on WPC extrusion lines (granulators, extruders, upstream and downstream machines, etc.) and now the company has accumulated a lot of experience on WPC equipment, molds, technical formula, and products.SKY WIN wood-plastic machines are sold to over 200 customers in China, and over 30 customers in foreign countries, such as Itly, Russia, Poland, Singapore, Thailand, Saudi Arabia, UAE, Honduras, etc..

SKY WIN Technology Co., Ltd. is a high-tech joint-stock enterprise which combines research, manufacture and sales of WPC (wood-plastic composites) extrusion machines in China.In the past 10 years, many experts in SKY WIN have concentrated on WPC extrusion lines (granulators, extruders, upstream and downstream machines, etc.) and now the company has accumulated a lot of experience on WPC equipment, molds, technical formula, and products.SKY WIN wood-plastic machines are sold to over 200 customers in China, and over 30 customers in foreign countries, such as Itly, Russia, Poland, Singapore, Thailand, Saudi Arabia, UAE, Honduras, etc..-

About SKY WIN

- Company Event

- HR

- Honors

- CULTURE

- About us

- Products

Our product

- News

- 2018 China Shanghai ...

2018-04-20 09:55:56

第三十二届中国国际塑料橡胶工业展览会 中国 上海 虹桥 国家会展中心

- PVC塑胶地板优势汇总 2016-03-02 08:32:00

- 环保地板,地板行业发展的必然趋势 2016-03-02 08:30:58

- IranPlast2016 Fair 2016-02-29 15:42:54

- News Category

- Company News

- Industry News

- Fair

- 2018 China Shanghai ...

2018-04-20 09:55:56

- Tech Support

Tech Support

Tech Support

- Tech Support

- Tech Support

- Quality Control

- Tech Service

- Tech Exchange

- Customers

- Inquiry Now

- Video

- Contact Us

苏公网安备32011202000012号

苏公网安备32011202000012号